Management of items allows to create and maintain set of items available in the system, assigning items to stock locations to allow operations with them on physical devices through SFI application and track items usage and availability.

To start working with items, access Items option in Data management menu.

On item list view following options are available to manage items:

|

Opens detail of selected item |

|

Creates new item |

|

Deletes selected item. Deletion is not possible if there are any assignments to stock location |

|

Opens import window to download data from external system |

|

Allows to update selected items from external catalog. Change selection mode to multiselect to allow selection of more items |

|

Allows to change selection mode to multi select to select more items |

|

Triggers selection of columns to show on item list. Selection is saved per user |

|

Allows to filter items shown in the list by several criteria. All active filters are listed above item list with option to clear them |

|

In combination with multi select allows to change information for more items in one batch operation |

|

In combination with multi select allows to assign items to device in one batch operation. |

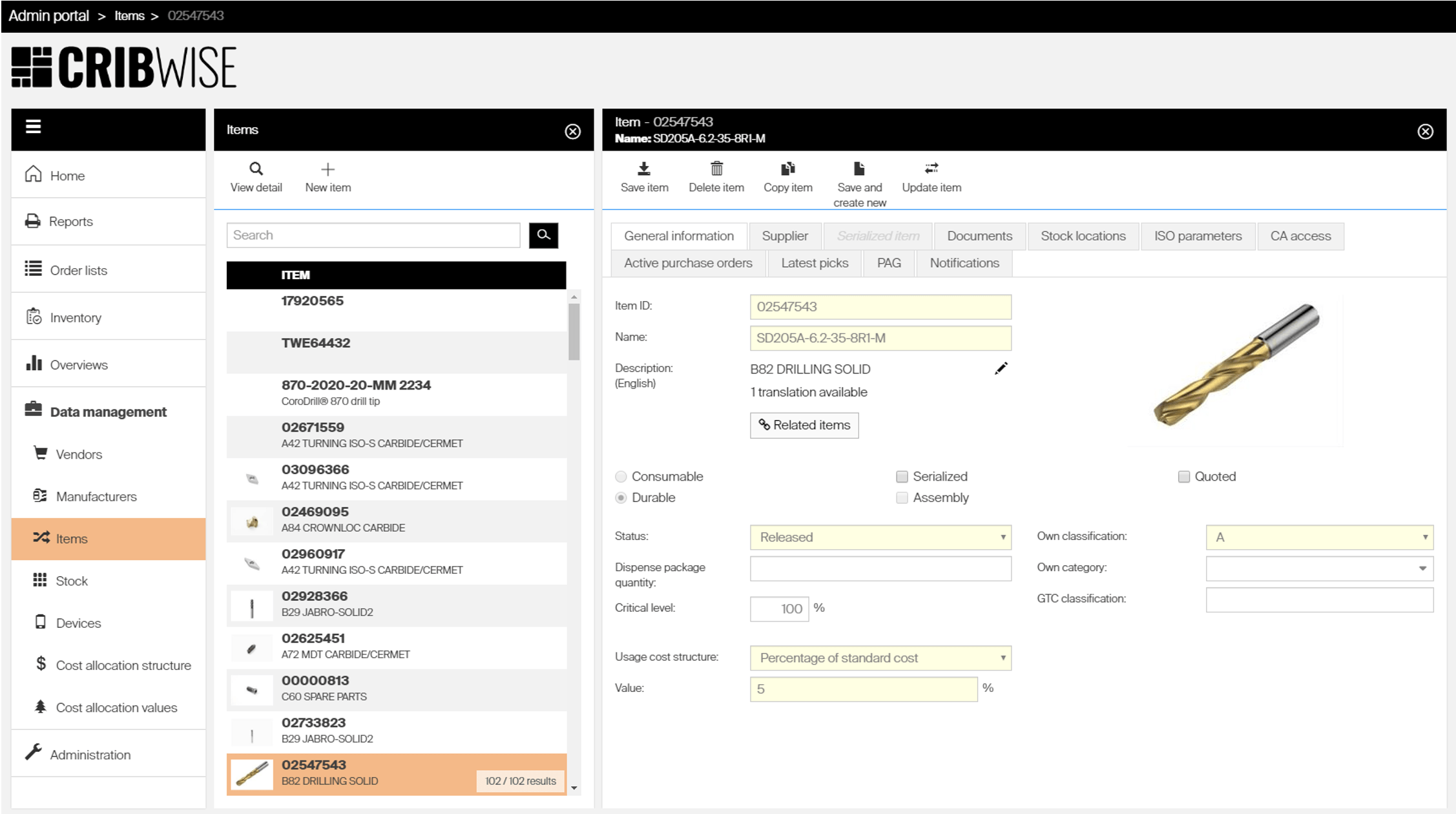

On item detail following options are available to work with opened item:

|

Saved performed changes |

|

Deletes selected item. Deletion is not possible if there are any assignments to stock location |

|

Creates new item based on copy of opened item |

|

Saves current item and opens new window to define new item |

|

Allows to update selected items from external catalog. |

General information

| Option name | Functionality |

| Item ID | Unique item identifier |

| Name | Name of item used for identification |

| Description | Item description shown together with item id or name based on system settings. Item description can be translated to different languages. Description shown to a user depends on language specified for the user or the system (when language is not set for a user, default language set in system settings is used to display descriptions). If description in desired language is not available, default description is shown. |

| Related items | Allows to show and set relations to other items. |

| Consumable/durable | Specifies if item can be reused and returned back to system. Some options are disabled for consumable items. This option cannot be changed once item status is set to ’Released’ state |

| Quoted | Specifies if item requires a quote for purchase. If set to true, item will not be automatically added to purchase orders by scheduled script (it still can be added to orders manually). Also when restocking quoted item from purchase order, it could be selected to restock more pieces than initially ordered. Such action will increase total number of ordered items in the order and will generate additional purchase transactions. |

| Serialized | Sets if each physical item is identified by unique serial number. This number is then entered for each operation in SFI to identify items. New serial numbers can be entered to the system during restock and assign operations on SFI |

| Assembly | Specifies, if this item is an assembly. Assemblies can be composed from multiple consumable or durable items with required quantities. Only durable item can be set as assembly. Assembly behave like durable item, with exception that it cannot be added to purchase order. If required quantities of items, from which assembly is composed, are available on device, new assembly piece can be composed from these items. |

| Status | Status of the item (see Item life cycle for more information): Defined – item can be assigned from AP, but cannot be restocked, picked or purchased Defined (imported) – item has been created by import from catalog, ERP, GTC package or Tool Library. Meaning of the status is similar to Defined Phase in – item can be assigned to locations and purchased, but is not offered for pick Released – item can be picked and purchased Phase out (Outgoing)– item can be picked, but cannot be added to purchase order. Item still can be added to transfer list to request quantity from central stock to satellite device Obsolete – item can be only returned and cannot be added to purchase order or transfer list |

| Own classification | Sets classification of item in ABC system. Used to prioritize ordering of items |

| Own category | Can be selected if category tree is defined in the system settings. Filtering on AP and SFI lists can be done according the selected category |

| Dispense unit of measure | Defines unit of measure for dispense of item. This unit of measure will be than used for all operations on SFI and for all transactions. Different unit of measure for purchasing can be set on supplier tab. For more information, see units of measure. |

| Dispense package quantity | Dispense package quantity of item. Used when restriction to pick only package quantity is selected on device. Coil storage devices will always force users to pick package quantities. When scheduled script will add item to transfer list to move quantity from central stock to satellite device, item will be always added only in multiples of its dispense package quantity. If item is already assigned in a location of machine able to dispense only packages (like ASK200), this quantity cannot be changed if there is any physical quantity in a location of that machine. To change the quantity, empty the location using inventory or remove assignment to the location. |

| GTC classification | Information about GTC class |

| GL account | General ledger account. This information is stored for any transaction made for an item and can be used in reporting. |

| Critical level | Sets percentage of order point (from item – device assignment) when item is considered at critical quantity in this device. Default is 100%. Example: order point in device is set to 20, critical level is set to 10%. Item is considered at critical quantity if physical quantity in this device is bellow 2 Actual critical quantity is displayed in item overview. |

| Usage cost structure | Sets how cost of pick is determined. Four options are available for durable items: Percentage of standard cost of item Usage cost is determined by percentage of standard cost of the item per dispense unit. Fixed price per pick Usage cost per dispense unit is manually set. Price per time of usage Usage cost is calculated by time period when item was out in production (time between pick and return). Cost for this time period is manually set. Per item state Usage cost depends on state of picked item. When picked item was new, usage cost is set to purchase price of the item per dispense unit. If item was refurbished, usage cost is set to service price of the item per dispense unit. If item was used, usage cost is zero. For consumable items, usage cost is always determined as 100% of standard cost. |

| Specify loan time | Available only for serialized items. Allows to specify maximum time, for how long user is allowed to have this item picked |

| Max allowed time | Specifies time allowed for pick of this item. After pick of this item is made, user is informed about maximum date and time before item must be returned. If time is exceeded, user is informed about this by warning after login to SFI. If set, notification about this situation can be sent to authorized person. |

| Automatic scrap period | Specifies time after which items not returned in allowed time will be considered as lost. Scrap period is calculated after allowed time is exceeded and item is not returned. When scrap period is reached, item is marked as scrapped. User is no longer allowed to return this item and purchase of a new item can be triggered. |

| Special handling for restock and return | If selected, operator must manually choose target locations during restock and return of the item instead of let system to choose these locations automatically. Operator can override physical maximum quantity on a location and place higher quantity if it can fit. Items with special handling can be restocked and returned only to open storage devices. |

| Prompt user to returned picked item during picking | If selected, picking flow will check if item selected to be picked is already picked in production (by any user). If yes, operator is prompted and allowed to return the picked item to service, scrap it or recycle it (based on item type). See return/scrap during pick for more information. |

| Track lot numbers | If selected, each transaction on an item will store lot (batch) number involved in this transaction. Lot numbers will be needed to be entered during any action adding new units of item to a stock (restock or assign). See lot and batch tracking for more information. |