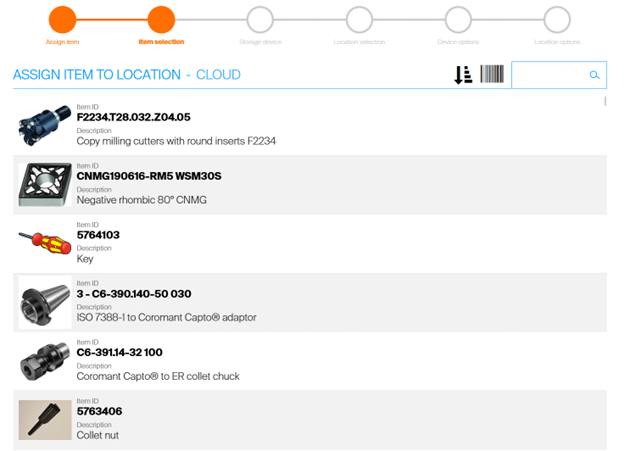

To assign new item to location, select Assign item option under Stock management menu or in Manage item view.

Assignment wizard will be started.

To navigate back between wizard steps, click to step name or circle in top progress bar

Select item to be assigned from list of all items in system. Flow will proceed automatically after item is selected.

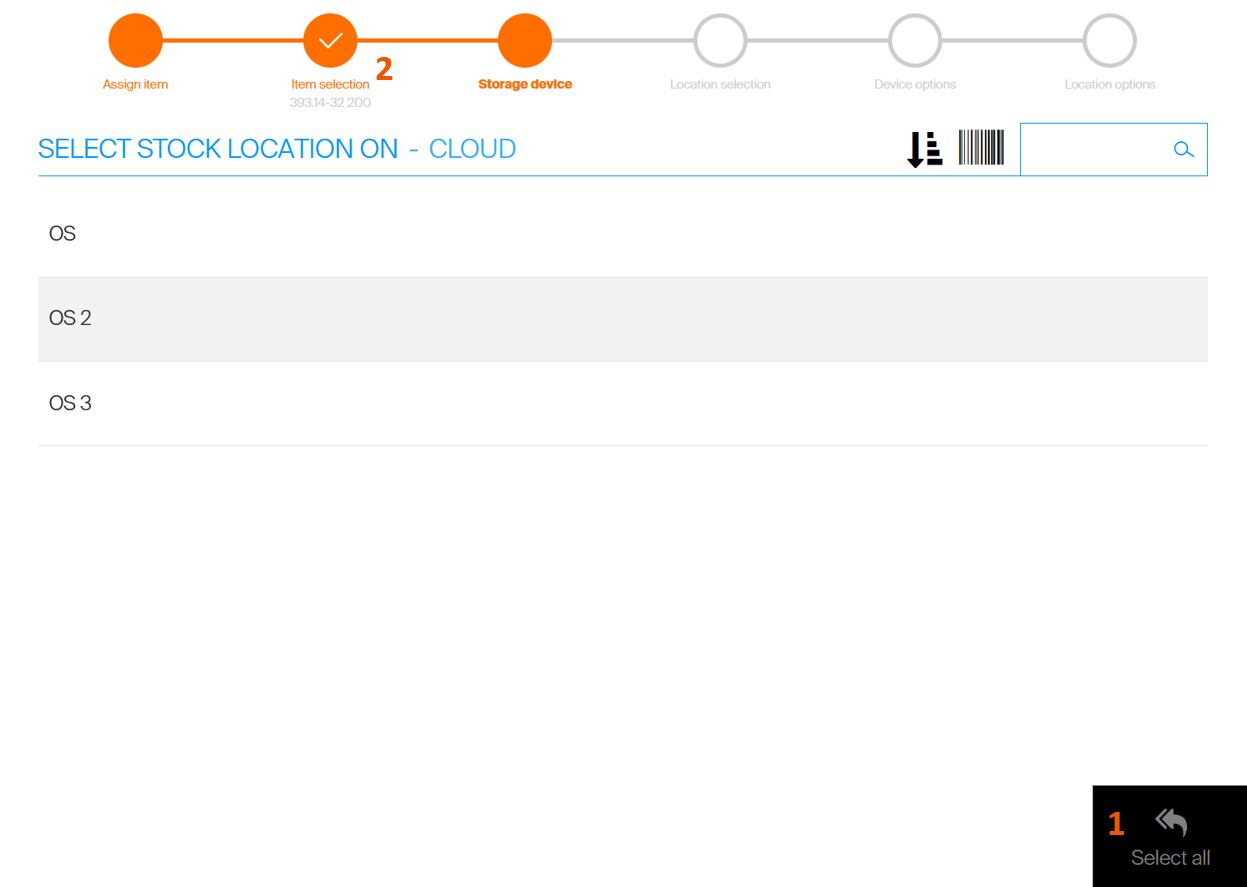

If there are more storage devices or storage modules in current device, SFI will allow to select specific one to filter out locations. To see all locations, press Select all button

(1). To navigate back in the wizard to change your selection, click to step circle in wizard progress

(2). If there is only one storage device or only one module, step to select storage device and module will not be visible in the wizard

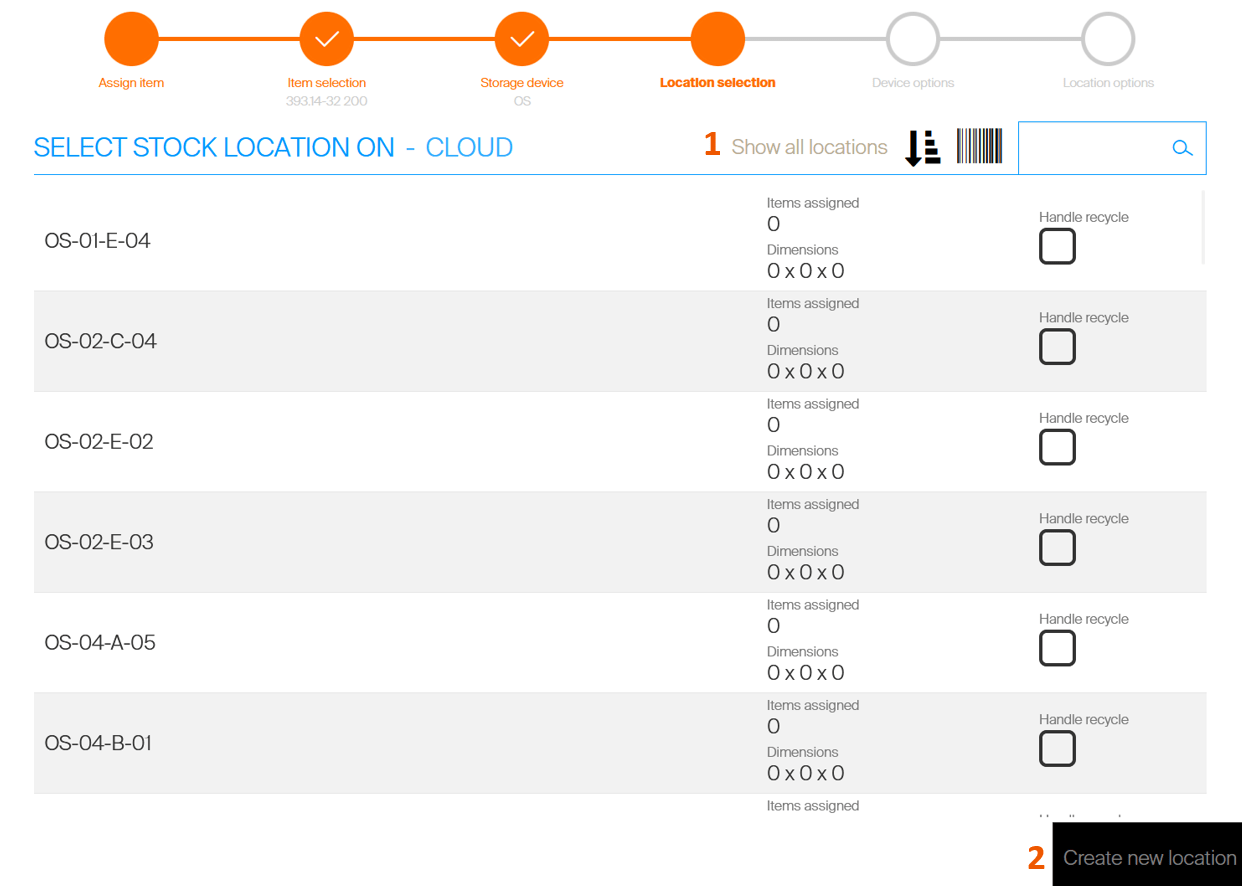

From list of locations, select location to assign item into. Locations can be filtered to show only that with no items assigned

(1). For specific types of storage devices, option to create a new location will be visible

(2), allowing to create a new location and proceed to assign the item to this location. Select location to proceed with the flow.

If location is grayed and cannot be selected, such location has been disabled by system administrator and it cannot be used for new assignment On ASK200 location can be selected by scanning location code

Purchase information for device assignment must be entered before item can be assigned to a location. If item is already assigned in device, device assignment information will be prefilled according previously entered values. Fill the purchase information to proceed.

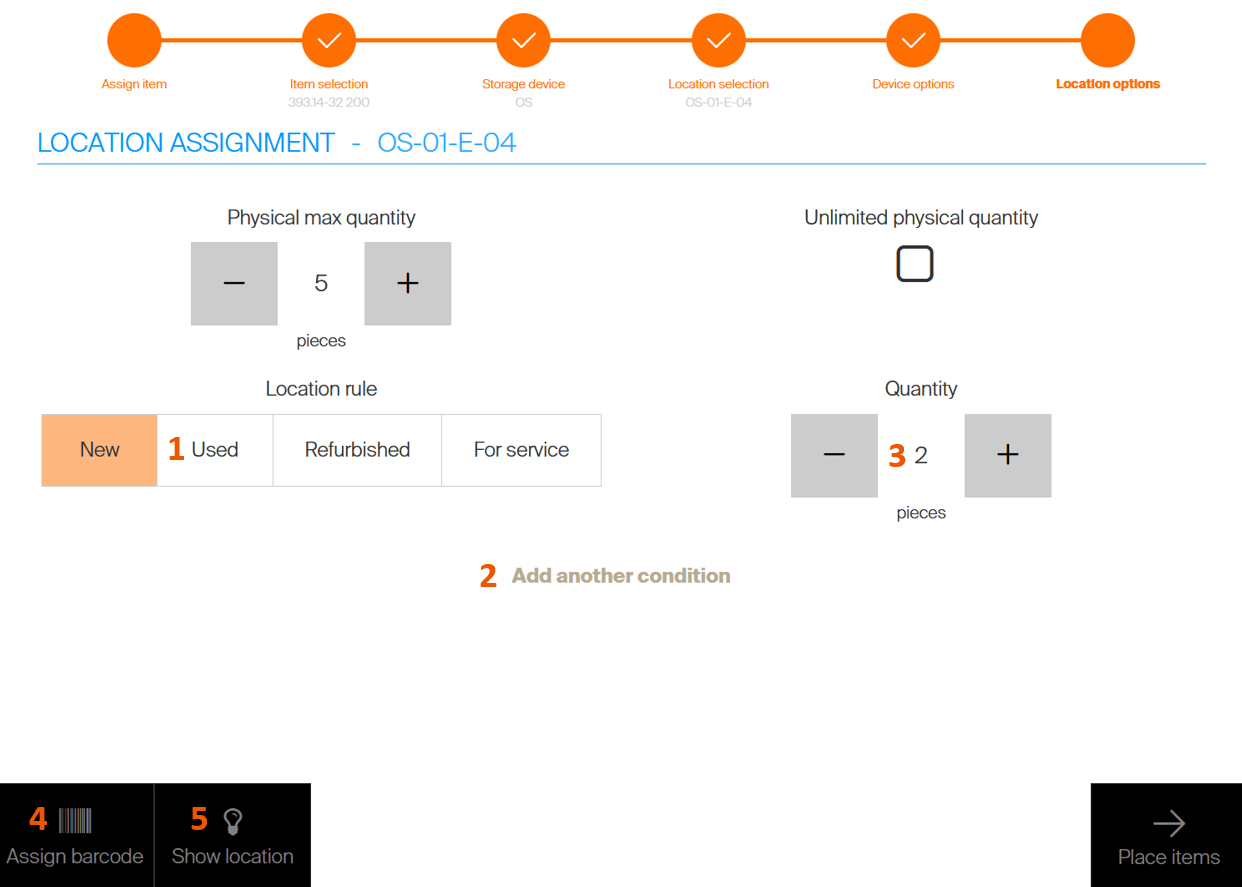

As the last step, information for selected location should be filled, specifying how many items can fit into the location and what conditions of the item will be stored there. For durable items, condition of item in the location must be specified

(1). Location will then contain only items in selected condition. It is possible to have several conditions for the item in single location. To setup such scenario, select to add another condition

(2). Serialized items are assigned to a location without a condition. Condition of each specific serial number is tracked specifically for this number based on its usage It is possible to directly place physical items during the assignment flow. To do that, fill Quantity information to specify how many items will be placed in specific condition

(3). Physical quantity in a location (regardless the condition) must not exceed the Physical max quantity If item which is being assigned, has no barcode it is possible to assign a barcode to this item during the assignment flow. To assign a barcode, press Assign barcode

(4) option and scan barcode of the item via scanner. Barcode cannot be changed via SFI once it is assigned. On controlled types of devices, Show location

(5) button can be pressed to open or show selected location to allow check maximum physical quantity. Select Save or Place items button to continue. If Quantity is set higher that 0, flow will continue to allow placing item in the location.

As the last step location can be filled with physical items (if physical quantity has been set in previous step). Based on storage device type location is opened to enable to fill items. Select filled quantity, fill items and close location or confirm fill operation. If item is serialized, enter serial numbers of new items. Each serial number must be unique for this item. It is possible to set target service date during assignment of serialized items (date when item will be automatically set to service). To set the date, press ![]() button to open detail of restocked serialized number and click to

button to open detail of restocked serialized number and click to  button to pick a date (the option is not visible if service is not activated for an item). If filled quantity is equal physical maximum quantity on the stock location, system will prompt to assign this item to additional location. After confirmation additional location for the item can be selected.

button to pick a date (the option is not visible if service is not activated for an item). If filled quantity is equal physical maximum quantity on the stock location, system will prompt to assign this item to additional location. After confirmation additional location for the item can be selected.