Orders can be one of two types – purchase and service.

Purchase orders contain list of items to be purchased from vendor. Service orders contain list of existing items to be send to service vendor to service these items.

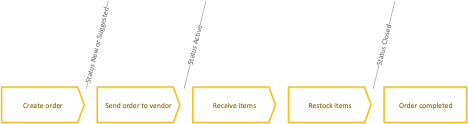

Life cycle of purchase orders and service orders is illustrated in following flow:

Create order

- Order has been created manually or automatically by scheduled script

- Items can be added to order and ordered quantity can be changed

Send order to vendor

- Order has been set to Active state manually or automatically by scheduled script

- If integration is setup with a vendor, order is sent to the vendor to process

- Items and ordered quantities cannot be changed

- Expected date is generated according vendor and item lead time and can be changed manually

- Items can be cancelled from order

- Order is visible for restock in SFI and received quantity can be changed

Receive items

- Since order is in active state, items can be marked as received on both AP and SFI

- Items are automatically marked as received after restock

Restock items

- Since order is in active state, items can be restocked on SFI

- If required, restock operation increases also received quantity

Order completed

- When all items are restocked or cancelled, order is automatically set as Closed

- No changes can be made on closed orders

If order contains custom items (items not created in system), order is closed when all custom items are set as received. Receive operation for custom items must be performed from order detail in Admin Portal

Create service order

- Service order has been created manually or automatically by scheduled script

- Items can be added to order and ordered quantity can be changed

- Only items in service locations or serialized items that require service can be added to service order (items must have external service vendor defined)

Send order to vendor

- Order has been set to Active state manually or automatically by scheduled script

- If integration is setup with a vendor, order is sent to the vendor to process

- Items and ordered quantities cannot be changed

- Expected date is generated according item service lead time and can be changed manually

Pick items for service

- Since order is in active state, items to service can be picked for service from SFI and sent to vendor

- Once item is picked for service, it will appear as in service.

- Items picked for service can be scrapped in case when service cannot be performed.

Receive items

- Since items has been picked for service, items can be marked as received on both AP and SFI

- Items are automatically marked as received after restock

Restock items

- Since items has been picked for service, items can be restocked on SFI

- If required, restock operation increases also received quantity

Order completed

- When all items are restocked or scrapped, order is automatically set as Closed

- No changes can be made on closed orders

According described flows, orders are in one of following states:

| New | Order has been created manually. Items in the order can be managed (added, removed). |

| Suggested | Order has been created by scheduled script with setting ’Create order as suggested’ or minimum order value set on vendor has not been reached. Items in the order can be managed (added, removed). |

| Active | Order is in process. When status is changed to ’Active’, order is send through defined channels to vendor. Order can be activated manually or automatically (’Create order as suggested’ option on scheduled script settings is switched off and minimum order value on vendor is not set or is reached). Items cannot be changed in this state. Active orders are synchronized to specified device to enable restock and goods received operations on SFI |

| Closed | All items ordered are restocked or canceled. Order is considered as fully delivered. |

| Cancelled | Order has been cancelled |

To start working with orders, select Orders in the main menu. List of orders have following options:

![]() Opens detail of selected order

Opens detail of selected order

![]() Creates new order manually

Creates new order manually

![]() Deletes selected order On order detail following options are available to work with opened order:

Deletes selected order On order detail following options are available to work with opened order:

![]() Saved performed changes

Saved performed changes

![]() Set order to ’Active’ state (from ’New’ or ’Suggested’ state) and send it to vendor through channels specified in ’Send options’ tab

Set order to ’Active’ state (from ’New’ or ’Suggested’ state) and send it to vendor through channels specified in ’Send options’ tab ![]() When order is in ’Active’ state, send order again to specified email or FTP target defined in ’Send options’ tab

When order is in ’Active’ state, send order again to specified email or FTP target defined in ’Send options’ tab

![]() If target email or FTP is defined in ’Send options’, this option allowing to create a preview of the order without sending it to the vendor. When order is prepared, download can be performed from notification bar

If target email or FTP is defined in ’Send options’, this option allowing to create a preview of the order without sending it to the vendor. When order is prepared, download can be performed from notification bar

![]() Allows to cancel ’Active’ order

Allows to cancel ’Active’ order

![]() Deletes opened order

Deletes opened order

General information

| Option name | Functionality |

| Order type | Type of order. Purchase or service can be selected |

| Custom order ID prefix | When selected, specific order ID prefix can be entered, which will be valid only for this order and will override Default order ID prefix value set on vendor detail. This information can be specified only when new order is created and cannot be changed for existing orders. |

| Vendor | Defines target vendor where this order will be send |

| Stock | Defines stock for which this order is created |

| Device | Defines device from selected stock for which this order is created. Leave empty if order is created on stock level |

| Consignment | Sets that order will contain consignment items. If option is selected, only items consignment items can be added to this order manually or by scheduled script. Cannot be specifed if consignment is turned off in system settings. |

| Purchase order reference | Order reference can be entered. Orders can be filtered according this information on SFI during restock process. If Frame order number is specified on vendor detail, reference is set automatically to value of this field when order is created automatically by a script |

| Custom Ship to ID | When selected, specific Ship to ID information can be entered, which will be valid only for this order and will override Default Ship to ID value set on vendor detail. This information will be sent to target vendor when B2B or XML order integration is setup or can be be included in PDF and Excel orders. |

| Custom Customer number | When selected, specific Customer number information can be entered, which will be valid only for this order and will override Customer number value set on vendor detail. This information will be sent to target vendor when B2B or XML order integration is setup or can be be included in PDF and Excel orders. |

| Notes | Allows to add custom notes |

If B2B integration is setup and order has been sent through this channel, additional information is displayed when order acknowledgment is received back from vendor (received by vendor date, tracking number, shipping date).

Ordered items

Ordered items tab contains list of items inside selected order.

Based on order status several operations can be done on ordered items. For new and suggested orders items can be added, removed or ordered quantities can be changed.

Based on system settings custom items can be added to purchase orders (items not defined in the system, these items cannot be restocked).

For orders in active state, for each item ordered received quantity and cancelled quantity can be set. Items cannot be added or removed or ordered quantity cannot be changed (with exception for items allowing overstocking, described further).

If B2B integration is setup and order has been sent through this channel, expected date to receive each item can be obtained from vendor response. For all ordered items manual change of expected date is available on order item detail.

On orders in closed or cancelled state no changes are allowed. Quantity of ordered items shown in an order on AP is always in purchase units of measure.

When an order is synced to SFI to allow restock, all quantities are recalculate to dispense units of measure and the restock process is then performed in those units. Prices of ordered items shown in an order PA are always in vendor’s currency.

Transactions related to orders (purchase, goods received, restock transactions) then show prices both in system currency (recalculated according conversion ratio valid in time, when order has been sent to vendor) and vendor’s currency.

When order is created automatically from scheduled script, items and quantities are filled by the script. Following options can be used to work with ordered items:

![]() Adds new item to the order. Only items assigned to device selected on order information can be added. If order is created on stock level, device must be selected for each item added. For service order only items located in service locations and serialized items marked for service can be added to the order

Adds new item to the order. Only items assigned to device selected on order information can be added. If order is created on stock level, device must be selected for each item added. For service order only items located in service locations and serialized items marked for service can be added to the order

![]() Opens details of ordered items with item quantities and history of quantity changes. Changes on ordered, received and cancelled/scrapped quantities and expected dates of delivery can be changed from the detail based on order status

Opens details of ordered items with item quantities and history of quantity changes. Changes on ordered, received and cancelled/scrapped quantities and expected dates of delivery can be changed from the detail based on order status

![]() Removes item from the order

Removes item from the order

![]() Adds new custom item. Information for custom item must be filled. Custom items can be only received from vendor, but cannot be restocked to SFI

Adds new custom item. Information for custom item must be filled. Custom items can be only received from vendor, but cannot be restocked to SFI

When service order is created, only items marked for service (such in service locations or serialized items automatically marked for service) can be added to the order. Items must be in ‘Released’ state and must have service vendor selected When purchase order is created, only items of vendor specified by order and assigned to selected device can be added to the order. Items must be in ‘Released’ state.

Send options

On send options tab channels for communication with vendor can be selected.

When order is set to ‘Active’ state, order is send to all selected channels in selected formats.

If order is created automatically from scheduled script, these settings are set according scheduled script settings.

B2B, Web service, FTP and email settings are set on specific vendor detail

For PDF and Excel format template can be selected to override vendor default template. List contains only templates of type order from system settings.

When email is selected as a channel, it is possible to specify custom content (subject and body) of the email. This setting will override email content setting set for vendor.

History

History tab shows all status changes of current order with information about date of each change.

Overstocking

Purchase orders can allow overstocking of ordered items, allowing to restock more items than have been initially ordered. For every overstocked item new purchase transaction is generated.

Overstocking could be done via AP by increasing purchased quantity for ordered item or via SFI during restock process by selecting higher quantity for restock that was ordered initially.

Overstocking is possible only for items which fulfill one of following conditions:

- item is set as quoted, or

- item’s vendor allows overstocking of non-quoted items.

Overstocking from AP

To increase number of ordered items from Admin Portal, open detail of order in state Active.

In list of ordered items, open item which allows overstocking. Change Purchased quantity to desired new value.

The field is not visible if opened item does not allow overstocking. Confirm the change to reflect new value. Purchase transaction will be generated to cover the increase.

The Purchase quantity value could be increased only. To cover goods which will not be delivered, increase Cancelled quantity instead.

Overstocking from SFI

To perform overstock from the Shop Floor Interface, start restock process and select order to be restocked.

On the next step, increase Quantity to restock above value of Available for restock.

Option to increase the value above the limit will be disabled if item does not allow overstocking.

Confirm the overstock and proceed with restock flow. Purchase transaction will be generated to cover the increase.

Partial order delivery

CRIBWISE supports scenario when new items should be delivered from a vendor over a time period rather than via single delivery. For such cases it is not needed to create separate order for each delivery, but it is possible to send single order to the vendor specifying requested delivery dates for each item line inside this order.

The requested delivery date can be used for purchase orders only. It cannot be used for service orders.

To setup the the requested delivery date for an item line, open order which has not yet been sent to a vendor (i.e. is in status New or Suggested).

Select to add new item to the order or select to edit item line already added.

Set value Requested delivery date to a date when this line should be delivered from a vendor. It is possible to have the same item multiple times in single order and to specify different Request delivery date for each line.

Ensure that the information will reach the vendor before sending the order:

- If sending of orders to vendor is in XML format (via B2B, to webservice, FTP or email), the Requested delivery date will be automatically present in the XML file.

- If sending of orders to vendor is in PDF or Excel format, the Requested delivery date is not part of default order template. Update the template to include the information (see Managing order templates for more details).

The Requested delivery date can be then shown as a column in list of items in an order, during restock flow and in reporting (in Orders data source).

The date will not impact the restock flow – if item is delivered sooner than requested, it will be possible to restock the item line in a standard way.