Lot tracking allows to track lot (or batch) numbers for selected items. Any transaction on tracked items will contain the number, so any movement of item (pick, return, restock…) can be related to specific lot or batch.

Once the tracking is activated for an item, any restock operation will ask operator to specify lot numbers of the item being restocked.

These lot numbers are then stored for the item and will be added automatically to any transaction made for this item.

Operators performing daily use operations (like pick or return) cannot impact what lot of item will be involved in the operation.

To ensure that lot numbers of non serialized items are not mixed, each location where tracked item is placed (each item-location assignment) can contain only items sharing the same lot number.

Item with another lot number can be placed to this location only when all items of the other lot number are taken out fully. Lot numbers are not bound permanently to a location.

The location is available for any other lot number as soon as all items are taken out.

This may increase need for storage capacity for an item in case when several lots occur at the same time. If one durable item is assigned to single location with multiple conditions, each condition can have different lot number.

Tracking lots for serialized items will set lot number for each serial number specifically. Thanks to that, it is possible to place serial numbers of different lots to single location. Working with serialized items is further described in dedicated section of this article.

Working with the lot tracking

To activate the tracking for an item, navigate to item detail, General information tab, and turn on option Track lot numbers. Once activated, it will impact daily use flows for the item as follows:

- Any future restock operation of that item (from order, service, transfer or without order) will require to input lot numbers of the item being restocked.

- Any future assignment operation to location will require to input lot number of the item being assigned in case when item is being assigned with physical quantity.

- Any future inventory operation will require to input lot number in case when inventory of location with quantity inside but without a lot number is being performed (this may happen when tracking of lot numbers is turned on for item which is already in locations).

- Changing quantity of the item in a location via Excel import will require to specify lot number of the item in the location.

- Any future operation will show what lot number is involved in the operation when operator is taking item out of a location or placing item to it.

If this option is turned on for item which is already in location, lot number of units in this location will be unknown. Inventory operation of this location will enforce the lot number is specified.

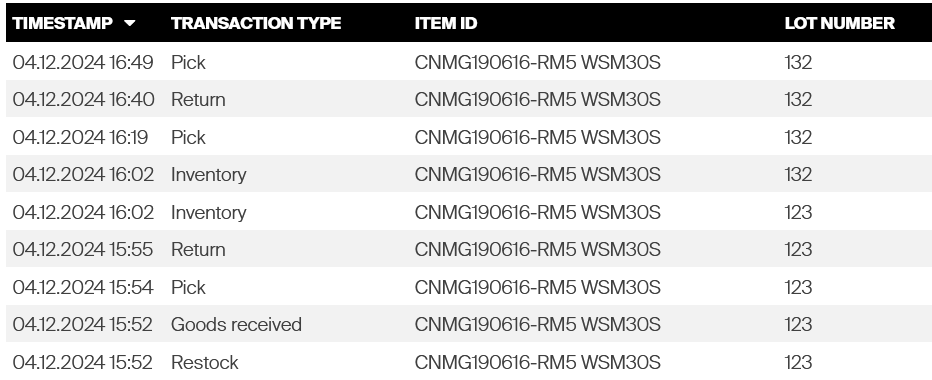

Once the option is active, any transaction made on an item will store the lot number involved in the transaction. This information can be shown in reporting by adding column Lot number to reports based on Transactions data.

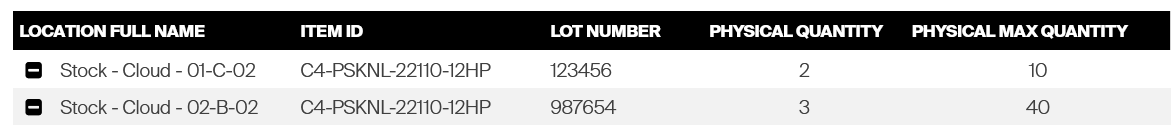

To get overview of which lot number is in which location, column Lot number is available for reports based on Locations data.

Restock items

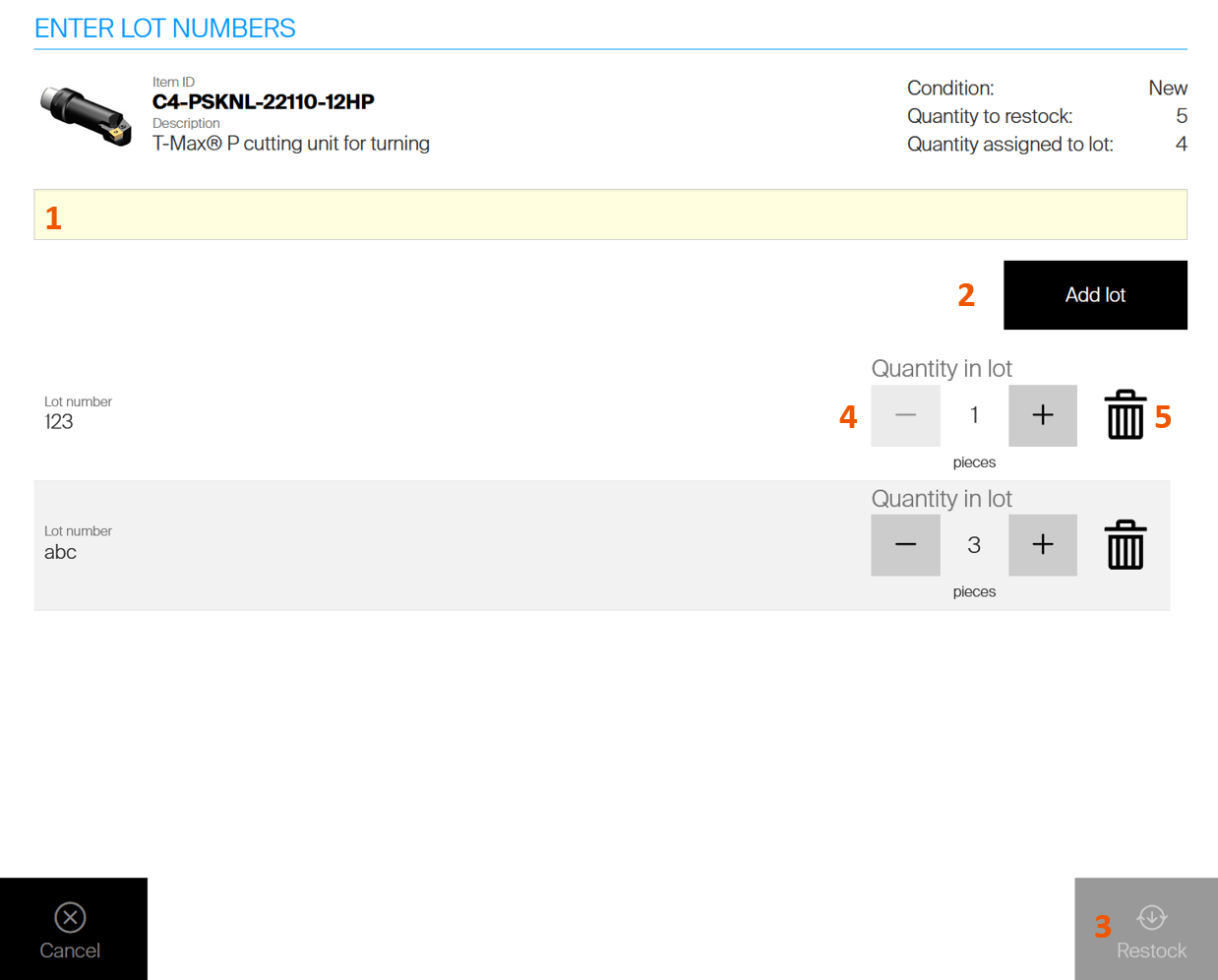

If there is any item tracking lot numbers during restock, operator will be asked to specify lot number for such item before restock can continue. For each item tracking the numbers following screen is shown right after quantity to restock is confirmed:

To proceed with restock of this item, all quantity selected to be restocked on the previous step must have lot numbers assigned. Enter lot number for the item (1) and confirm it (2).

It is not possible to proceed with restock until full quantity to restock has lot numbers assigned (3).

To add multiple lot numbers, decrease quantity of a lot number (4) and add a new one.

Entered lot number can be cleared by trash bin icon (5).

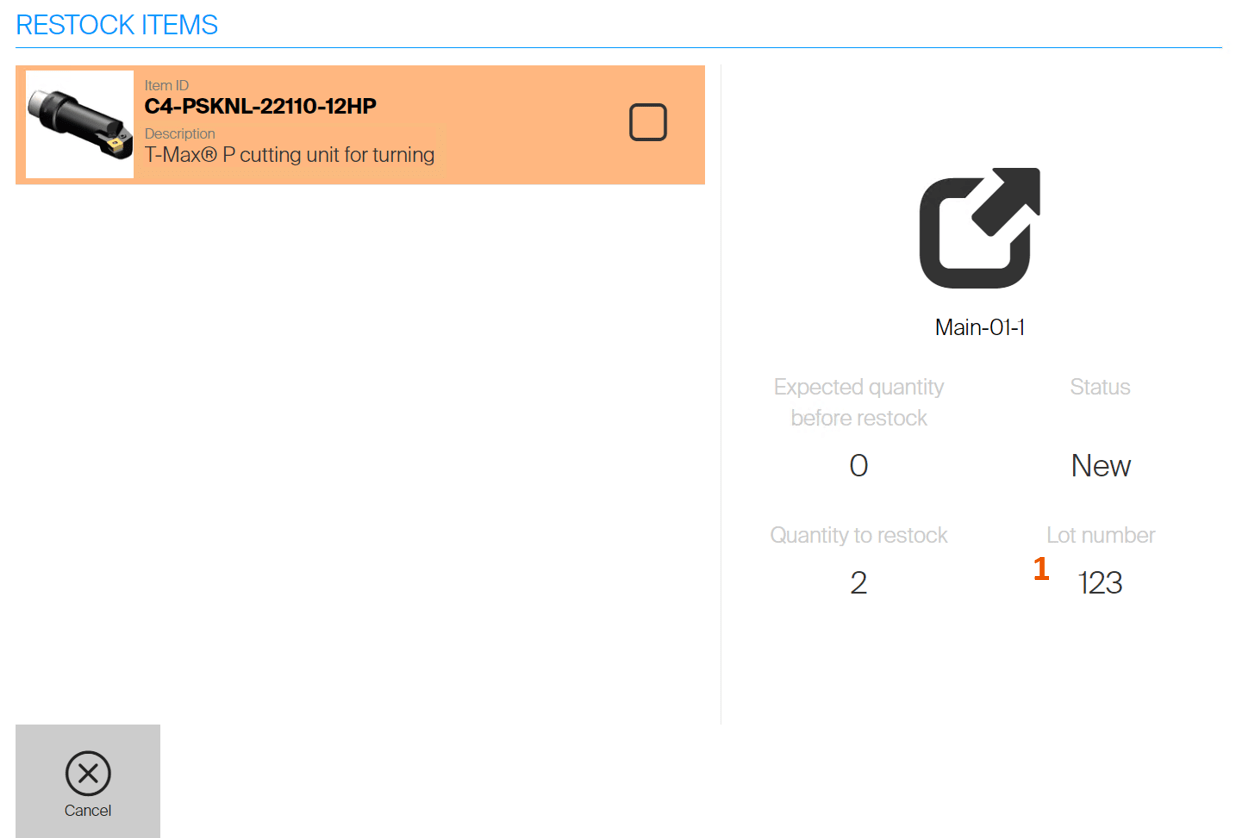

Clicking the Restock (3) button will allow to place this item to target location(s) to finish the restock of this item before proceeding with restock of all other items.

Information about which lot number and quantity should be placed to a location is shown (1).

If there is no suitable location available, information about not enough space is shown. New assignment must be created or restocked quantity lowered in order to proceed.

Once restock is confirmed, restock flow continues with another item tracking lot numbers or with all remaining items.

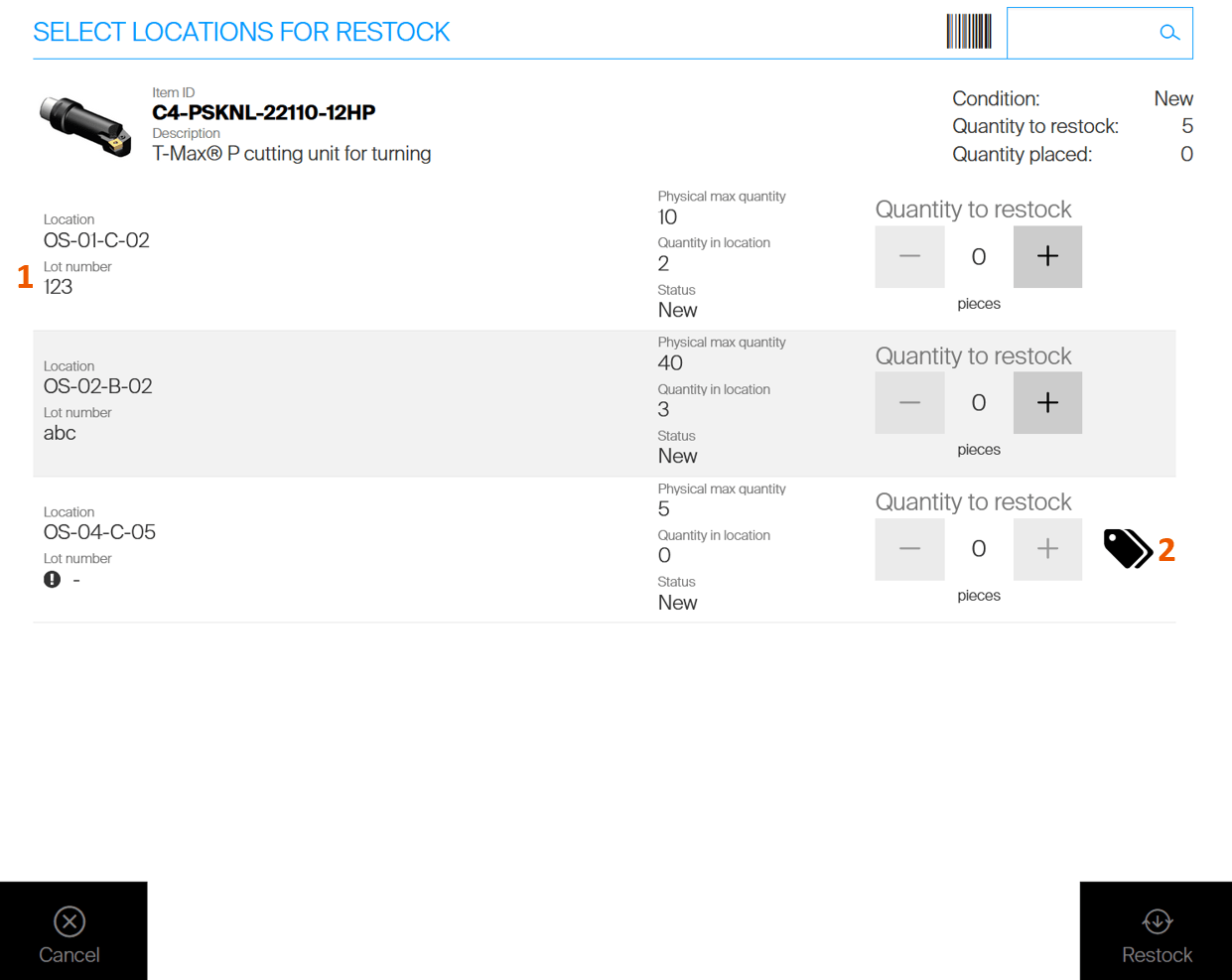

Restock items with special handling

If item is tracking lot numbers and also has special handling, lot number must be entered for each location where this item is about to be placed.

All locations already containing the item will show lot number assigned to that location (1).

If restocked items are of the same lot number and there is space available in such location, restocked quantity can be added. If lot number of restocked item is different or there is not enough space in already occupied locations, new lot number can be assigned to empty location (2).

Lot number must be assigned before it is possible to restock item to this location.

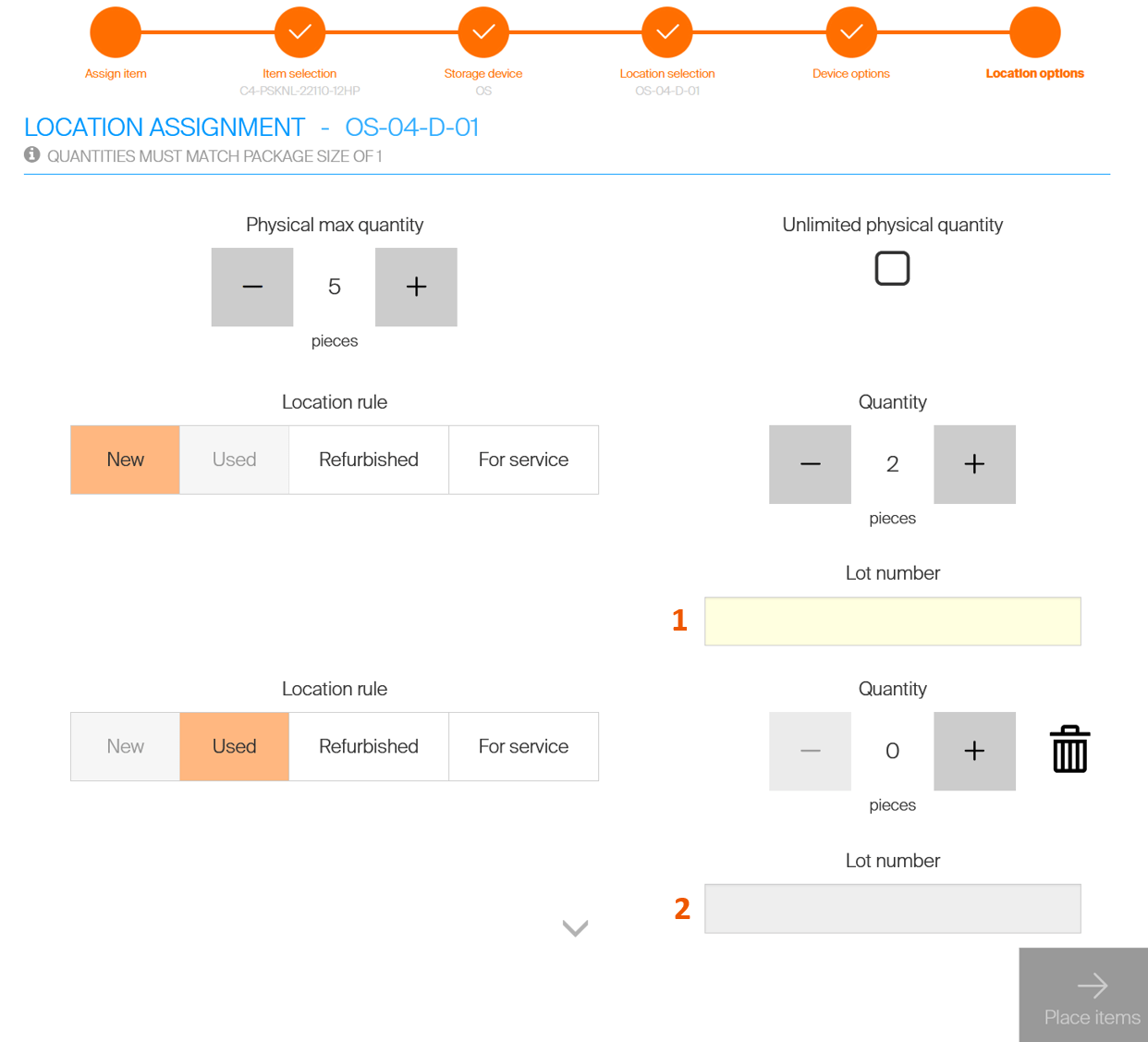

Assign item to location

When item tracking lot numbers is being assigned to a new stock location, it is needed to enter lot number for that location in case when physical quantity is being placed to the location during the process.

On Locations options step in assignment wizard, if Quantity being placed to a location is not zero, lot number for this quantity must be specified (1) before it is possible to proceed with the assignment.

If item is being assigned with multiple conditions, lot number must be specified for each condition separately (2).

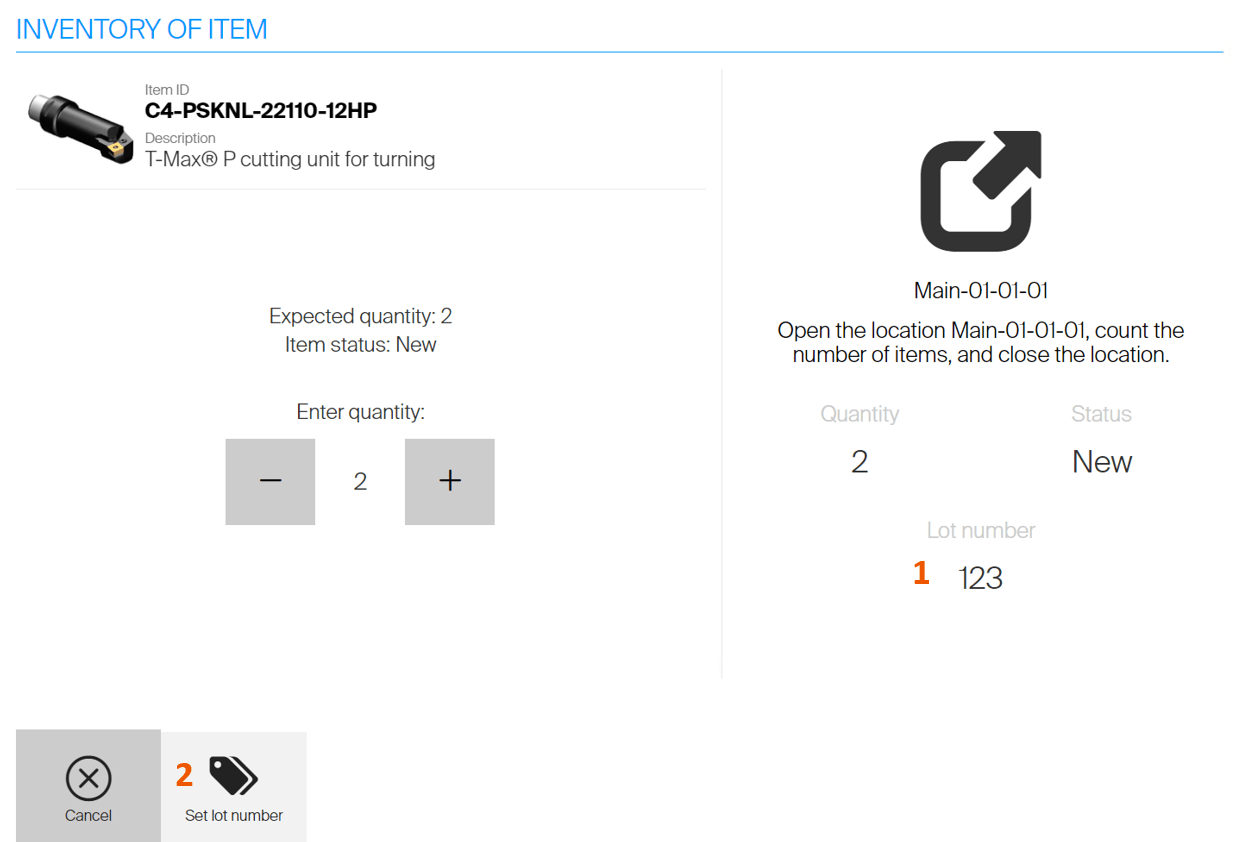

Inventory

During inventory of item tracking lot number, expected lot number is shown during the inventory process.

Expected lot number is shown with expected quantity in a location (1).

If the lot number is not valid (or is not set at all), it is possible to change the number (2).

This action will generate inventory transaction removing the former lot number and another inventory transaction placing the new lot number to the location.

If there is no lot number for the location, it is not possible to finish inventory until the lot number is specified.

Changing lot number

Lot number of an item specified during restock or assign cannot be freely changed and is bound to this item in the location. Only option to change lot number of the item is to perform inventory or adjust quantity in location (via SFI or Excel import).

In both cases, such change is tracked in transactions, with first transaction covering removal of the old lot and second transaction covering placement of the new lot.

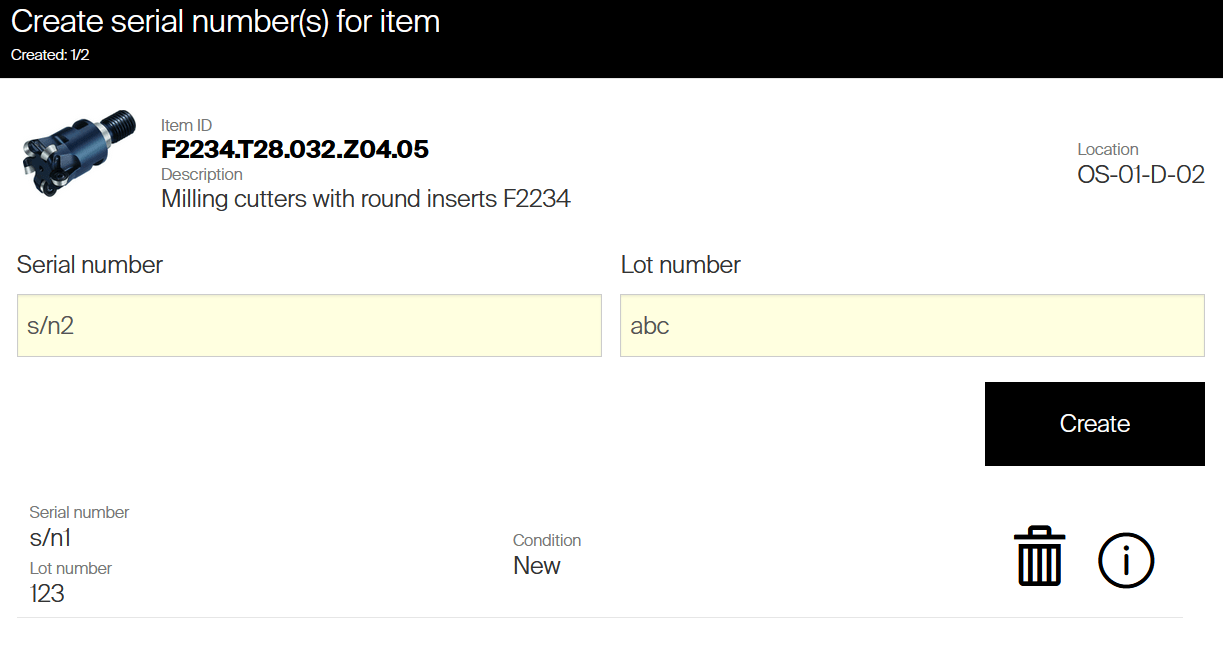

Lot tracking for serialized items

As serialized items allow to track each specific instance (serial number) of an item, lot number is stored for each instance separately.

Instances with different lot numbers may be combined in single location, still allowing the system to track lot number for every transaction made on specific serial number.

During creation of a new serial number (during restock or assign flows on SFI or import from Excel), lot number must be entered for each new serial number.

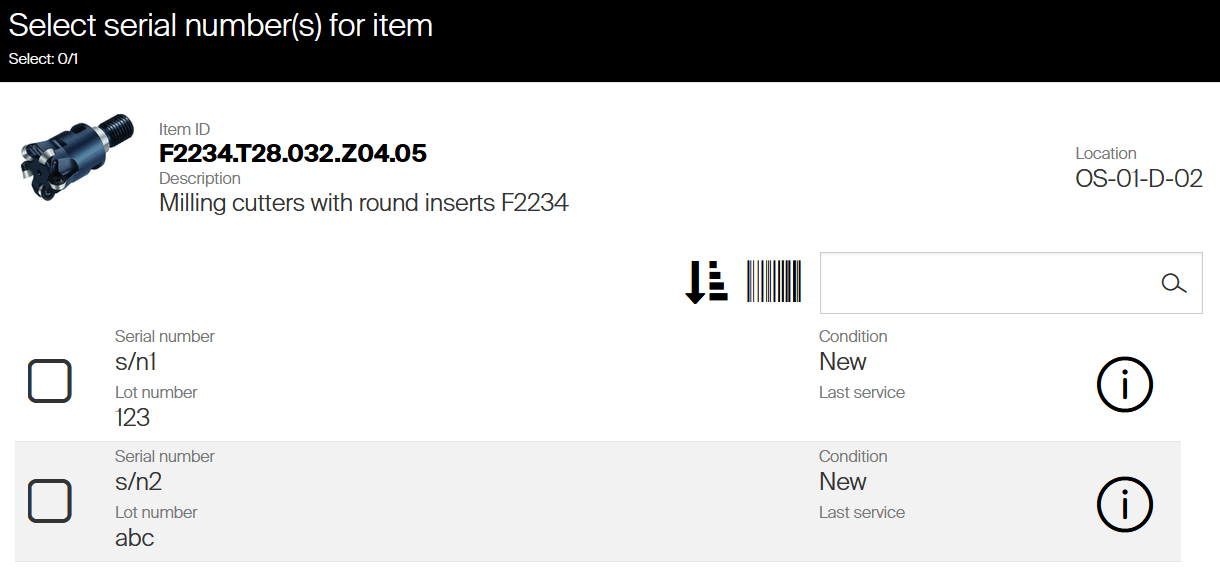

Any time when existing serial number for an operation is needed to be selected, lot number assigned to that serial number is shown.

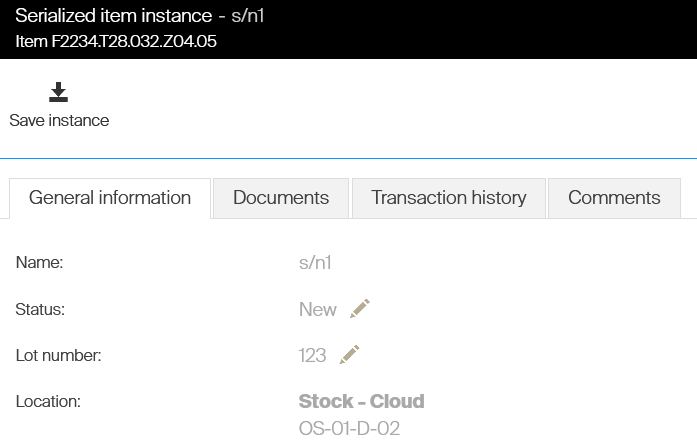

The lot number of each specific serial number can be also seen on detail of that serial number and can be added as a column to Serialized items overview on Admin Portal.

Changing lot number of an instance

Unlike the non serialized items, lot number of serialized item cannot be changed during inventory.

If discrepancy is found, it is possible to change the lot number from detail of affected instance from Admin Portal.

Navigate to Serialized items overview and click to the serial number, or open detail of the item and select the serial number from Serialized item tab.

Select Edit for current lot number and confirm the new number.

Similarly to inventory, this change is covered by transaction to remove former lot number from a location and place the new lot number instead.

If the lot number is changed for serial number which is currently not in any location, no transaction will cover this change.