Our offer

Connect and control your existing Hänel Lean Lift Storage device solution by CRIBWISE.

We give the simplicity to operators on the shopfloor to work with only one point of use storage solution software that is simple and intuitive. Same follow-up capabilities for all tooling and indirect supply, one integration to ERP system!

CRIBWISE continues its journey to connect the shopfloor logistics, create visibility and simplify for operators and storage personnel.

Hänel Lean Lift Storage device controller work through normal SFI and can be set-up by selecting Hänel as a Storage device solution.

CRIBWISE does not sell the physical storage unit or the required Hänel HOST-COM server.

CRIBWISE connects to the Hänel HOST-COM server that needs to be configured for CRIBWISE when set-up/installed by Customer or Hänel representative.

Storage device settings

- Type: Location controlled

- Manufacturer: Hänel Lean-Lift Multi-Space

- IP address (including port number) must be specified to point to Hänel controller.

- Lift number must be specified to distinguish between multiple machines connected to single controller. In case of single lift, value is 1.

- Access point number must be specified in order to properly address opening of the machine. In case of single opening, value is 1.

- Number of trays must be specified to set how many trays will be in the machine

- Tray dimensions (width and depth in millimeters) must be specified to set dimensions of each tray where locations can be placed

- Grid size can be specified to define what can be the smallest possible location size on a tray

Prerequisites for Integration

- Hänel HOST-COM controller up and running

- The controller must be accessible over TCP/IP from PC, where SFI will be installed (it could be direct connection or connection over company’s network).

- The controller must enable host communication. This must be done after restart of the controller (after system boots up, press Enter until following message appears

or after performing manual operation

or after performing manual operation

Following information must be obtained and provided during creation of new storage device on AP:

- IP address of the controller.

- Access point number, typically 1 in case of single opening (access point).

- Lift number

- Tray dimensions

- Number of trays

Operation modes

There are two options how the device can operate:

- With safety equipment and remote control module – machine can be fully controlled remotely. After sending remote command from SFI, movement will start. This mode works the same as other lift machines. We have tested this mode only via simulator.

- Without safety equipment – machine can be controlled remotely, but every movement must be confirmed on machine’s panel. All SFI flows then work in following way:

- User requests f.e. an item to pick.

- SFI sends command to the lift and inform user to attend machine’s panel. Machine’s panel shows prompt to start movement.

- User starts movement by confirmation on machine’s panel.

- SFI will allow to confirm operation once tray arrives in an opening.

- User selects that operation is finished (f.e. item taken out from location) on the SFI.

- SFI shows prompt to attend machine’s panel again to store tray back to the machine. Machine’s panel shows prompt to start movement.

- User starts movement by confirmation on machine’s panel.

- SFI continue with a flow, i.e. fetch another tray or show summary

Module Structure

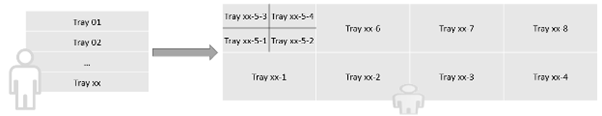

- Each tray stands for separate module

- For each tray in the machine (based on setting when storage device was created) empty module is created

Stock location structure in a module

- Locations created by device admin on SFI

- Each location has specific width and depth and its place in a tray (=module) defined by X and Y coordinates

Modules and locations structure

Locations on tray are always named from front left corner to back right corner of the tray, starting from 1. Sublocations are always named in the same manner in scope of their base location, extending name of the base location.

Limitations

- Only single opening can be controlled.

- LED bar is not supported.